Hartman Brothers - Allair supplies all of your beverage grade gas needs across the Western Slope of Colorado to help your business run efficiently and profitably.

Customer service and satisfaction is our mission. We provide the most environmentally friendly beverage carbonization systems and high-purity nitrogen and blended gas systems in Montrose, Grand Junction, and Ouray, CO.

If your business is on the Western Slope of Colorado, Allair can help you with your beverage grade gas and equipment needs.

How a Soda Fountain Works

Beer Styles Introduction

Dangers of Liquid CO2 Venting

This is an important video that highlights the danger of Cryogenic Liquid CO2 venting experienced by the Phoenix Fire Department. Allair Green CO2 Systems help prevent this type of incident!

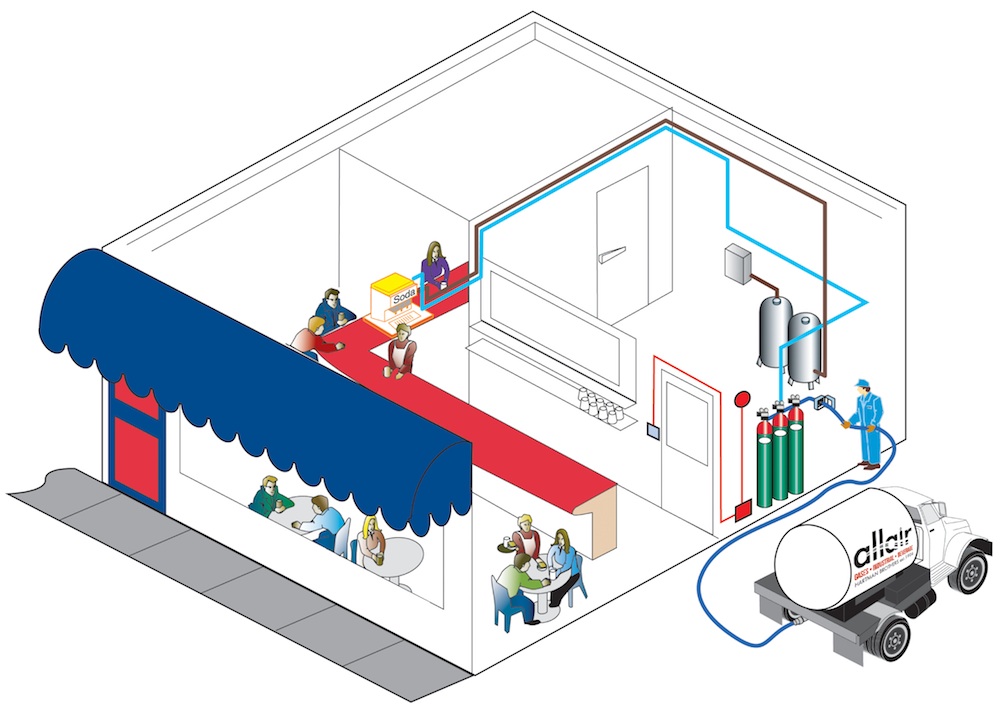

Green CO2 System

Eliminate the worry of changing your Carbon Dioxide (CO2) tanks during busy times. Staff interruptions are eliminated because the tanks no longer require switching. Save money by retaining previously lost carbon dioxide through venting or changing tanks.

How It Works

The Allair Green CO2 system is a collection of high-pressure receivers, custom sized to accommodate your business needs. The system features a patented Diverter Valve design that maintains consistent and constant pressure to your devices. It is easily filled from outside your facility. There is no interruption to your service during the filling process by the Allair tanker.

The Green CO2 System™Advantage

- No need to shut down your system during fill process

- No swapping out cylinders in the middle of a busy time

- No venting of the CO2 into the atmosphere, thus saving you money and reducing your carbon footprint

- No interruption of service during filling

Green CO2 is perfectly designed for:Green CO2 System

- Breweries

- Convenience stores

- Restaurants

- Water treatment

- Greenhouses

- Pools

- Sanitation applications

- Any business using CO2

Safety

- System is secured to the wall

- Eliminates the need for handling cylinders

- Zero pressure in fill line after filling

- Zero venting of CO2 into the atmosphere

- Optional CO2 flow detection with auto shutdown in the event of a downstream system leak

Basic Gas Cost

CO2, distributed in bulk, tends to be priced 20 to 25% less than CO2 distributed by your cylinder suppliers. As a result of the operational differences between bulk CO2 and cylinders, the Allair CO2 system reduces CO2 consumption 20 to 25% versus other delivery systems. With a Allair bulk CO2 system, no residual CO2 is returned to the supplier, no leaks occur when regulator changeovers are improperly connected, no product loss due to venting during filling process and downstream leaks are detected earlier due to having a single source of CO2 inventory measurement.

Associated Product Waste

CO2 cylinders are often changed only when it is discovered that the drinks are flat. In a store using 50# cylinders with an average monthly CO2 usage of 250#, this can occur four or five times per month. In cases when a store uses 20# cylinders, it is possible that flat drink situations occur 3 to 10 times per month as each 20# cylinder becomes empty. Wasted product costs arise when flat drinks are returned or are left at self-serve beverage stands. Further costs are incurred when an employee recharges the beverage system with CO2 by holding open the fountain heads and allowing syrup to pour down the drain. Flat drinks result in wasted syrup, cups, lids and straws.

Opportunity Loss/ Dissatisfied Customers

Also related to flat drinks are the loss of potential sales and dissatisfied customers. It is all too common that CO2 run-outs occur during peak rush periods. When this occurs, one of the employees must leave his/her job station, which removes the employee during the rush period for 5 to 15 minutes, possibly resulting in longer lines, customer walk-outs, and loss of related food item sales. Some customers may have left with a flat drink 'to go' and may never bother to return. If the backup cylinders are empty, the store could be out of CO2 for hours until an emergency delivery can be made.

Unnecessary Service Calls

CO2 supplied in cylinders can result in unnecessary service calls. When cylinders are allowed to go empty, the Brix calibration in the drink towers can be thrown off, resulting in the wrong portions of syrup, water, and CO2. Other possible causes for service calls include leaky regulator connections, improper regulator settings after repeated change outs, and damaged regulators which give false readings. The stationary and 'set it-forget it' features of the Allair CO2 Bulk System eliminates many of the unnecessary service calls that result in emergency charges to the store.

Labor Costs

Five change outs/month x 10 minutes/change out = 50 minutes wasted time/month

Training new employees on cylinder change outs, regulators, safety procedures, etc.

Cylinders are typically delivered once per week/month, resulting in one to four deliveries per month per location. Employee time is involved in tracking cylinder movement in and out of the store. With a Allair bulk CO2 system, there are no cylinders moved in and out of the establishment which eliminates the possibility of the establishment being billed for 'lost' cylinders.

Since the Allair CO2 bulk system is refilled from outside the establishment, no employee time is wasted in assisting suppliers during cylinder deliveries (i.e., opening the back door, getting the keys, checking and signing delivery tickets, identifying empty cylinders for pick-up).

Since cylinders must be moved, it is inevitable that this can result in handling accidents (i.e., sprained backs, hand or foot injuries). These cylinders are under very high pressure (800 to 1000 psig) and have the potential of becoming projectile in a tip-over incident or any number of dangerous conditions that can exist in a high pressure cylinder.

In contrast, the Allair CO2 bulk system never needs to be moved and it operates safely. This eliminates exposure to personal injury claims or lawsuits arising from cylinder accidents causing property damage or injuries to employees or the general public.

- Cylinder Change outs

- Training Time

- Accounting Costs

- Interruptions

- Safety

Maintenance Costs

During cylinder change outs, regulators inevitably get dropped and require repair or replacement. Wrenches needed to loosen regulators often are lost and must be replaced. The Allair CO2 system eliminates the need for wrenches and no regulator changeovers are ever required.

Miscellaneous Costs

Cylinder rental charges and/or deposits are eliminated.

Space savings are realized by eliminating the clutter of back-up cylinders. The Allair CO2 system can often be placed in unusable space since it does not require regular access.

The Allair CO2 system simplifies CO2 inventory management by providing a single source of measurement.

Since the Allair CO2 system is kept full through an outside filling station, backroom security is enhanced by eliminating the need for having the CO2 delivery person enter the store to make his CO2 delivery.

The safe, reliable choice for pH balance

CO2 is the safest, most reliable alternative to using muriatic acid to balance the pH level of your chlorinated water. Maintaining the desired pH level of your water is critical to ensure swimmers' comfort and safety. CO2 replaces acid and is regulated by your automatic control system. It provides several benefits to your operation.

- Ensure safe water conditions

- Improve water clarity

- Use fewer chemicals

- Have less damage to pool surfaces

Eliminates Dangerous Acids and Saves Money

By using CO2 you eliminate the dangers and costs associated with muriatic acid:

- No more use of acid feed pumps

- No more dangerous fumes in the mechanical room from the mixing of chlorine vapor and acid

- Minimizes mechanical room corrosion

- No costs incurred for acid feed pump maintenance or tubing replacement

- Our Allair CO2 system supplies continuous CO2 flow to meet your CO2 requirements.

Stationary, Automatic System

- Replaces all of your high pressure cylinders and eliminates cylinder change-outs

- Provides uninterrupted CO2 flow that is regulated by your automatic control system

- Permanently installed and requires no handling or adjustment

- Self-contained - no electricity required

Complements Your Automatic Control System

- Provides hands-free operation

- Factory pre-set components ensure correct operating pressure and flow rates

- Provides continuous CO2 flow with no run-outs

- Requires no employee monitoring or intervention

Provides Safer Enviroment

- No cylinder handling eliminates job related injuries

- Eliminates dangerous gas fumes

Dependable Deliveries

Allair CO2 trained technicians will properly install, fill, maintain and service your system. Our delivery personnel will:

Monitor your average CO2 use and refill your tank on a regular basis through the outside wall.

Use a metered delivery system that provides you with a receipt for the amount of CO2 delivered.

Added Convenience and Savings

Bulk CO2 Systems eliminate the hassles and costs associated with high pressure cylinders. Other benefits include:

Reduced CO2 use and cost by up to 30% with no residual CO2 returned to the supplier and lower overall CO2 usage cost.

CO2 can be delivered around the clock with no interruptions.

Reduced labor costs by eliminating cylinder change-outs and inventory control.

The use of CO2 for pH adjustment and control (neutralizing or lowering) has long been recognized as a cost effective alternate to Sulfuric Acid. Many companies have turned to CO2 for help with their environmental needs because it offers the following advantages:

Greater Control - as it reduces high pH levels quickly. It is then self-buffering as it reaches neutral pH levels. This self-buffering feature allows precise end-point control without the danger of overshooting into undesirable low pH levels.

Greater Safety - as CO2 is not stored as an acid solution.

Reduced Maintenance Costs - as CO2 requires less equipment and monitoring costs.

Greater Storage Capacity - convenient bulk systems make it possible to store up to twice as much neutralizing agent in the same amount of storage space with no increase in weight.

Reduced Labor Costs - CO2 requires no handling costs, and can be utilized via a completely automated system.

Extended Equipment Life - as CO2 is non-corrosive to pipes and equipment.

N2 Generator and Blending System

Allair Has The Food Grade Nitrogen System For You

Whether you are using Nitrogen for a blender, dispensing wine, nitrogenating, powering pumps or any other application, we have a Nitro-Draught system from Fizz Optimization Group capable of supplying an on demand supply of brewery grade™ nitrogen and blended gases. Gas blends can be customized to your exacting application!

Convenience

No more changing or running out. No more ordering or worrying which old fashion high pressure cylinder is full or empty. Much more effective use of space and employee training and labor.

Safety

Low operating pressure of Nitro-Draught versus the 2000 psig of those high pressure cylinders. Mounted, preventing cylinder changeover accidents. No more moving heavy cylinders or using wrenches!

Quality

Our food and beverage grade nitrogen is a minimum purity of 99.8% compared with the unknown quality of those old fashion high pressure cylinders. Endless flow maintains consistent food and beverage quality and customer satisfaction.

Savings

With a single, low monthly service fee, we will provide limitless nitrogen. No deposits, delivery fees, fuel surcharges, lost cylinder bills, multiple invoices to handle. With Nitro-Draught, we will improve your operation and improve your profit!

Applications

- Nitrogen blending systems

- Coffee dispense and nitrogenation

- Soda and Beer Pumps

- Wine preservation and dispense

- Brewery product transfer, tank inerting, nitrogenation

- And many, many more